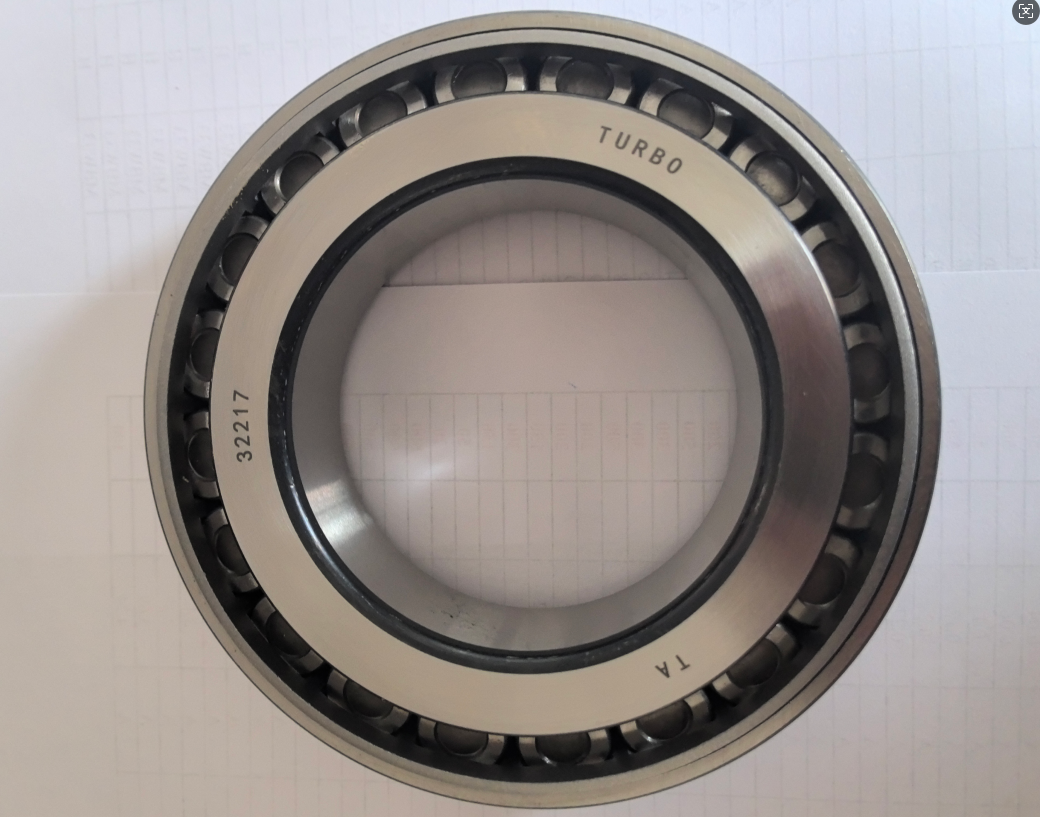

I32217ukuzala kuyinto roller tapered evamile kakhuluukuzala. Nasi isingeniso esinemininingwane yolwazi lwayo oluyisihluthulelo:

1. Uhlobo Oluyisisekelo Nesakhiwo

- Uhlobo: I-roller ene-tapered. Lolu hlobo lokuthwala luklanyelwe ukumelana nemithwalo ye-radial (amandla e-perpendicular ku-shaft) kanye nemithwalo emikhulu ye-axial unidirectional (amandla ahambisana nokuqondisa kwe-shaft).

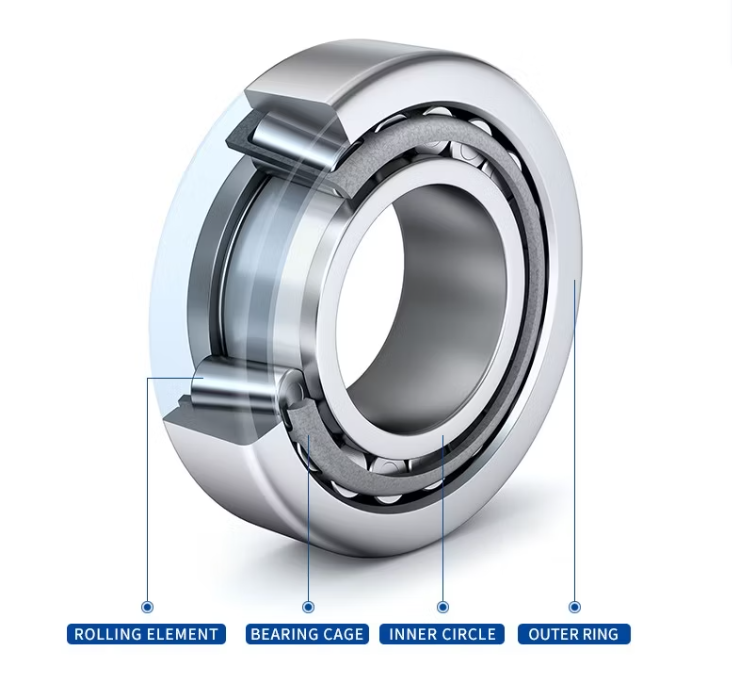

- Isakhiwo: Siqukethe izingxenye ezine ezibalulekile:

- Iringi yangaphakathi: Ikhoni enomgwaqo ocijile, ogibele ku-shaft.

- Indandatho yangaphandle: Inkomishi enomgwaqo ocijile, efakwe endlini yokuthela.

- Amarola ane-tapered: Izinto eziginqikayo ezimise okwe-Frustum ezigingqa phakathi kwemigwaqo yomjaho wamasongo angaphakathi nangaphandle. Ama-roller ngokuvamile aqondiswa ngokunembile futhi ahlukaniswe ngekheji.

- Ikheji: Ivamise ukwenziwa ngensimbi enesitembu, ithusi eliphendukile, noma amapulasitiki obunjiniyela, isetshenziselwa ukuhlukanisa ama-roller ngokulinganayo futhi kuncishiswe ukungqubuzana nokuguga.

2. Ukutolika Kwemodeli (I-ISO Standard)

-32217:

- 3 : Imele irola elicijile.

- 22 : Imele uchungechunge lobukhulu. Ngokuqondile:

- Ububanzi bochungechunge: 2 (ububanzi obuphakathi)

- Uchungechunge lobubanzi: 2 (ububanzi obuphakathi)

- 17 : Imele ikhodi yobubanzi obubhore. Okwama-bearings ane-diameter ebhokile≥20mm, ububanzi bebhore = 17× 5 = 85 mm.

3. Ubukhulu obukhulu (Amanani Ajwayelekile)

- Bore ububanzi (d): 85 mm

- Ububanzi bangaphandle (D): 150 mm

- Ububanzi/ubude (T/B/C): 39 mm (Lokhu ingqikithi yobubanzi/ubude bokuthwala, okungukuthi, ibanga ukusuka kumkhawulo omkhulu wendandatho yangaphakathi kuya ebusweni obukhulu besiphetho sendandatho yangaphandle. Ngezinye izikhathi ububanzi bendandatho yangaphakathi B nobubanzi bendandatho yangaphandle C kuyamakwa, kodwa u-T uyipharamitha yobubanzi obuvame ukusetshenziswa kakhulu).

- Ububanzi bendandatho yangaphakathi (B): Cishe bungu-39 mm (imvamisa bufana noma busondele ku-T; bheka ithebula lobukhulu obuthile ukuze uthole imininingwane).

- Ububanzi bendandatho yangaphandle (C): Cishe ngu-32 mm (bheka ithebula lobukhulu obuthile ukuze uthole imininingwane).

- Indandatho yangaphakathi enobubanzi obuncane bezimbambo (d₁ ≈): Cishe 104.5 mm (ekubalweni kokufaka).

- Indandatho yangaphandle enobubanzi obuncane bezimbambo (D₁ ≈): Cishe u-130 mm (ekubaleni ukufakwa).

- I-engeli yokuxhumana (α): Ngokuvamile phakathi kuka-10° futhi 18°, inani elithile kufanele lihlolwe kukhathalogi yomkhiqizi ophethe. I-engeli yokuxhumana inquma umthamo wokuthwala umthwalo we-axial.

- I-Fillet radius (r min): Ngokuvamile, i-fillet radius encane yazo zombili izindandatho zangaphakathi nangaphandle ziyi-2.1 mm (ngesikhathi sokufakwa, kufanele kuqashelwe ukuthi i-fillet yehlombe le-shaft kanye nehlombe lezindlu ezithwalayo akufanele libe lincane kunaleli xabiso).

4. Izici Zokusebenza Eziyinhloko

- Umthamo ophezulu wokuthwala imithwalo: Iqine kakhulu ekubekezeleni imithwalo ye-axial engaqondile, futhi ingathwala imithwalo emikhulu yama-radial. Amarola axhumene nemigwaqo yomjaho, okuholela ekusabalaliseni okuhle komthwalo.

- Ukuhlukaniswa: Umhlangano wendandatho yangaphakathi (indandatho yangaphakathi + ama-roller + ikheji) kanye nendandatho yangaphandle ingafakwa ngokuzimela, ekulungele kakhulu ukufakwa, ukulungiswa, nokugcinwa.

- Isidingo sokusetshenziswa okubhanqiwe: Njengoba ingathwala kuphela imithwalo ye-axial engaqondile, ezikhathini lapho imithwalo ye-axial ye-bidirectional idinga ukuthwalwa noma i-axial positioning eqondile ye-shaft idingeka (njengokushaywa kwe-shaft), i-32217 bear ngokuvamile idinga ukusetshenziswa ngamabhangqa (ubuso nobuso, ukulungiswa kwe-axial, ukuhlehliswa kwe-back-to-back) ukulayisha kuqala.

- Ukugunyazwa okulungiswayo: Ngokulungisa ukuma kwesihlobo se-axial phakathi kwamasongo angaphakathi nangaphandle, imvume yangaphakathi ye-bearing noma ukulayisha kuqala kungalungiswa kalula ukuze kutholwe ukuqina okungcono kakhulu, ukunemba kokujikeleza, nempilo yesevisi.

- Isivinini sokuzungezisa: Isivinini esikhawulayo sivamise ukuba ngaphansi kunaleso sama-deep groove ball bearings, kodwa sisengakwazi ukuhlangabezana nezidingo zezinhlelo zokusebenza eziningi zezimboni. Isivinini esinqunyiwe esithile sincike endleleni yokugcoba, umthwalo, uhlobo lwekheji, njll.

- Ukungqubuzana nokukhuphuka kwezinga lokushisa: I-coefficient ye-friction iphakeme kancane kunaleyo yama-ball bearings, futhi ukukhuphuka kwezinga lokushisa ngesikhathi sokusebenza kungase kube phezulu kancane.

5. Izinyathelo Zokufaka

- Ukusetshenziswa ngababili: Njengoba kushiwo ngaphambili, ngokuvamile ukufakwa ngababili.

- Lungisa imvume/ukulayisha kuqala: Ngemva kokufaka, indawo ye-axial kufanele ilungiswe ngokucophelela ukuze kuzuzwe imvume eklanyelwe noma ukulayisha kuqala. Lokhu kubalulekile ekuthwaleni ukusebenza kanye nempilo yesevisi.

- Ihlombe le-shaft kanye nezindlu lithwele ukuphakama kwehlombe: Kuyadingeka ukuqinisekisa ukuthi ukuphakama kwehlombe le-shaft kanye nehlombe elithwele izindlu ezithwalayo kwanele ukusekela indandatho yokuthwala, kodwa hhayi phezulu kakhulu ukuvimbela ukufakwa kokuthwala noma ukuphazamisa i-fillet radius. Ubukhulu behlombe kufanele buklanywe ngokuqinile ngokuhambisana nezincomo kukhathalogi yokuthwala.

- Ukugcobisa: Kufanele kuhlinzekwe ukugcotshwa okwanele nokufanelekile (ukugcoba amafutha noma ukugcotshwa kukawoyela) njengoba ukuthambisa kunomthelela omkhulu empilweni yesevisi.

6. Izinkambu Zokusebenza Ezivamile

Ama-roller bearings ane-tapered asetshenziswa kakhulu ezikhathini ezidinga ukuthwala imithwalo ehlanganisiwe ye-radial ne-axial, ikakhulukazi lapho imithwalo ye-axial inkulu:

- Amabhokisi ogiya (ukuhanjiswa kwezimoto, izinciphisi zezimboni)

- Ama-axles ezimoto (ama-wheel hubs, umehluko)

- Roll izintamo zezigayo eziginqikayo

- Imishini yezimayini

- Imishini yokwakha

- Imishini yezolimo

- Amaphampu

- Ama-Cranes

- Amanye ama-spindle amathuluzi omshini

Isikhathi sokuthumela: Aug-15-2025